| View the Video by click the model |

| Machine Name: JANDI'S T-SHIRT BAG MAKING LINE |

| Model : JIT-55 |

| Series : JIT-SD, JIT-MD, JIT-ST, JIT-MT |

| Model No. |

JIT-50 |

JIT-55 |

JIT-SS |

JIT-SD |

JIT-45D |

| Feature |

Mono-layer

Semi-Auto Type |

Mono-layer

Semi-Auto Type |

Mono-layer

Full-Auto Type |

ABA

Full-Auto Type |

2-Color

Full-Auto Type |

| Motor Size |

30 HP |

40 HP |

40 HP |

30 HP & 40 HP |

20 HP *2 |

| Material to be used |

Bio-Degradable Material / HDPE Resin / Filler (Caco3) |

| Bag Size |

350-900 mm (Max. 600 mm after gusset) |

| Take-Up Tower |

1 set, Roller width 700 mm |

| In-Line Printer |

Flexographic Printing, 1 - 6 colors (to be specified by buyer)

For Water based & Solvent based Ink

|

| Bobbin change unit |

1 set, for Non-stop operation |

| Bag sealing unit |

1 set, Heat-cutting type |

| Waste recovery unit |

1 set, to reuse the die-cut on-line |

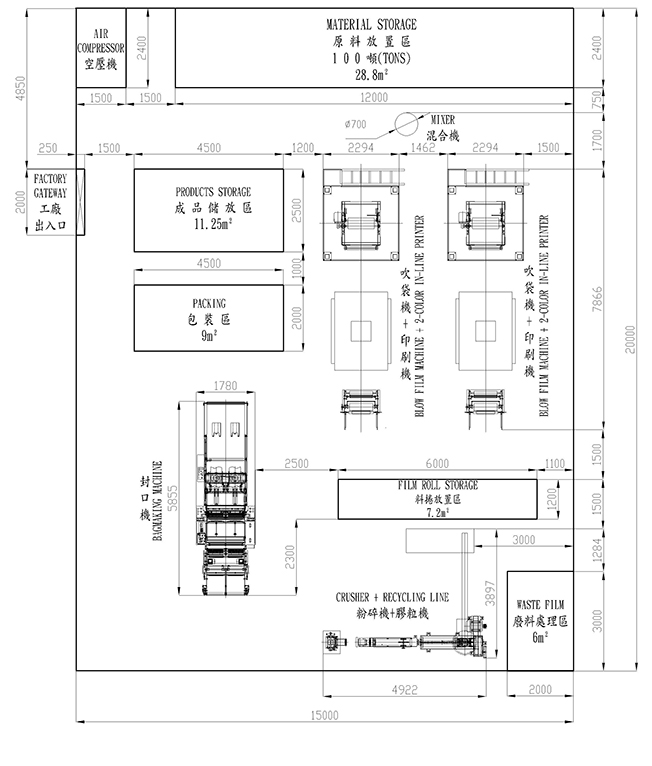

JANDI’S JIT T-SHIRT BAG MAKING LINE

– Green Design on Plastic Bag Making Machine

The advantaged features of JIT T-shirt Bag Making Line :

- Big saving on Power Consumption

- Less working space required for the same output

- Less workers required for the same output

- Less Human Error and minimize the management required

- ower Material Cost for making T-shirt Bags

- Best partner in using Bio-Degradable material for T-shirt Bags

- Better sealing quality, very strong sealing line

- Less Carbon Emission, less Carbon Footprint

As a Plastic Machinery Manufacturer, JANDI’S presented, since 2013, a patented and green design machine which makes no waste plastic left during processing.

The traditional way to produce T-shirt bags, it takes 100 tons of material to make average 85 tons of end products, and has to recycle average 15 tons of waste film from die-cut. But, by using JANDI’S JIT it makes nearly 100 tons of end products from the same amount of material.

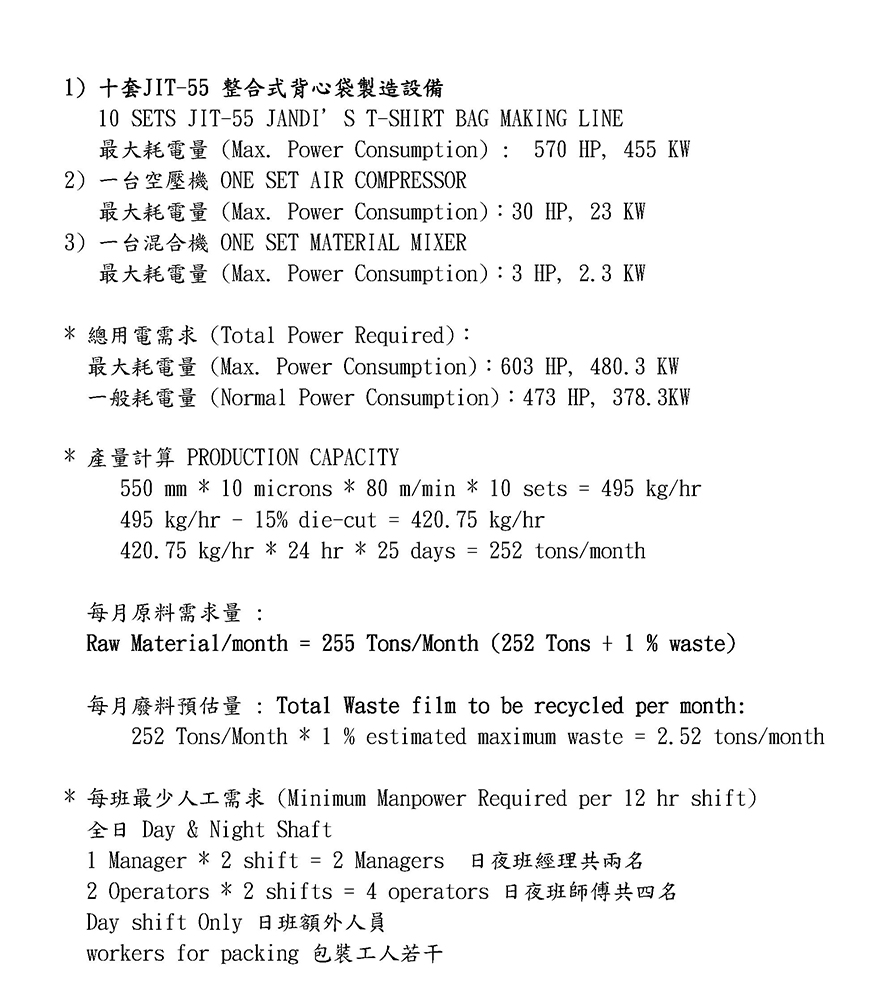

In making the T-shirt/Shopping bags, the general steps are as followings: First is to Blown Film, Second is Printing, and Third is to seal & cut the film into individual bags, and followed by the waste recycling of the die-cut. Which also takes a lot of space for storage and handling works in-between each process (also refer to attachment – 001)

The die-cut is the waste film cut-off from the bags to make the T-shirt form, and it is between 12% up to 18% of a plastic bag, in average there is 15% die-cut from each T-shirt/Shopping Bag. The recycling of the die-cut is a crucial point to the plastic bag manufacturing, which not only examines producers’ management and technology, because the colors, mixed material, cleanness of these die-cut could change the end products. But also increase a lot the power consumption & carbon emission during the recycling of the die-cut (crushing, washing, melting & pelletizing).

There is additional labor cost and processing cost to recycle the die-cut, but JIT runs the Blown film, Printing, Bag making, all in line, and reuse the die-cut on line during the production, make the end produce immediately, do not need any space to storage the semi-finished products between each process and has no additional cost for collecting, sorting, storage, handling in the recycling of the die-cut and to re-mix the recycled pellets with raw material. (also refer to attachment – 002)

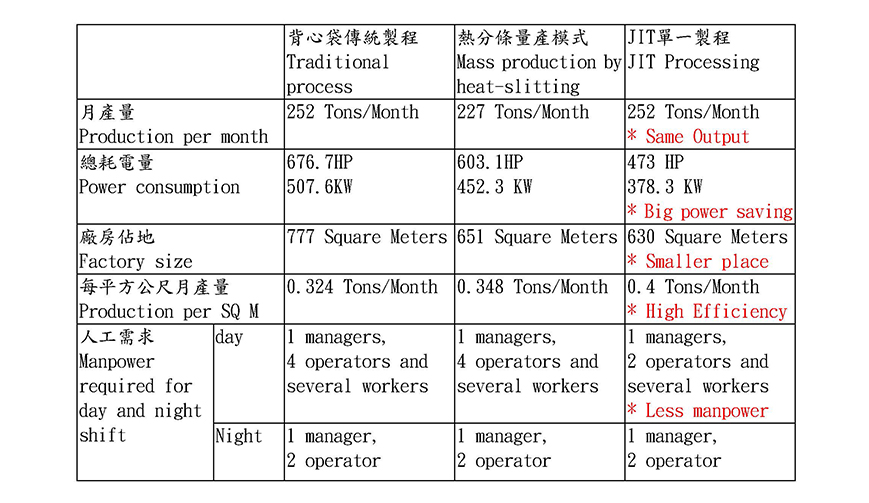

Comparing with the traditional way, JIT save up to 25% power consumption for the complete production and recycling process on T-shirt bag’s production. (also refer to attachment – 003)

In Traditional way to make T-shirt bags, first is to blown the film, then printing, then to make sealing & cutting :

For Blown Film :

Usually to make a film roll will take about 4 to 6 hours, depends on the diameter of the roll, and usually a bigger diameter also means less change-over and less waste in production.

And, the problem could be happened in the blown film process are :

- The film size (width & thickness) is not correct

- The color is not correct

- The film is not surface-treated, by corna treater, to be ready for printing

For Printing :

It takes about 3 to 4 hours to print each film roll

The problem could be happened in the printing process are :

- The printing quality is not qualified

- The ink is not dry enough before rewind

- The printing length is not stable (problem in Tension Control during printing)

For Bag Making :

It takes about 2 to 3 hours to cut & seal each film roll for making the bags.

The problem could be happened in the bag making (sealing & cutting) process are :

- The bag length is not uniform because of the printing length is not stable

- The sealing is not strong enough because of the abnormal operation in blown film.

Altogether, blown film 4 to 6 hours, printing 3 to 4 hours, bag making 2 to 3 hours, it is about 9 to 12 hours from the raw material to the end products, only after all these times then the quality of the end products could be examined. If there was any mistake during the processing, you might lose a lot from all these production.

By JIT, you can see and check the finished product as soon as the machine has been started up, which save you a lot of trouble and reduce all the human errors could be happened during the processing, minimize the management in production.

Green manufacturing & pollution caused by plastic film/bags are the major concerns about the environment protection. Bio-degradable material is one of the success solutions for these issues. However, one of the concerns, in using Bio-degradable material, is the cost is 2- 3 times higher than the normal plastic resin. And, it is also more difficult to recycle and reuse the Bio-degradable material, this makes the cost to Bio-degradable T-shirt/shopping bags become even higher. This makes the promotion of Bio-degradable material even harder. When using JIT, to produce T-shirt bags, the 12-18% die-cut is reused on line, this save partial the cost and difficulty in using bio-degradable material.

JIT in-line production process seals the bag when the film is still hot, the sealing line is melted together naturally, unlike the old traditional way has to make the sealing on the cold film, which requires higher temperature to melt/seal the film together and the sealing could become embrittlement cause the bags broken on the sealing line.

TEST RUN VIDEO﹝Scan﹞

TEST RUN VIDEO﹝Enter﹞

以月產量80噸背心袋的工廠來比較

Differences in 80 tons per month production

* JIT PLANT SAVED 35% to 41% POWER CONSUMPTION

JIT工廠節省37%到42%的用電

273A – 161A = 112A, at 380V/3P/50 or 60 HZ

273A – 161A = 112A, at 380V/3P/50 or 60 HZ

* JIT PLANT SAVED US$17,550 OPERATION COST MONTHLY

JIT工廠每月節省美金17,750的營運費用

93.6 TONS * 12.5% die-cut = 11.7 Tons * US$1500 = US$17,550.00

假設打孔(袋頭)只佔12.5%, 原料一噸美金1500

* JIT PLANT SAVED 140 SQUARE METERS (46.67%) SPACE

JIT工廠節省140平方米 (140/300 = 46.67%)的佔地

* JIT makes the best quality film & sealing, please check our testing report and get the sample and test it yourself.

JIT 吹膜品質和封口強度, 無可比擬, 請務必點閱生產工廠詳細資 料並歡迎索取樣品自行測試

Details of JIT Factory JIT 工廠詳細資料

月產量80噸背心袋, 使用兩套JIT-55

T-SHIRT BAGS 80 TONS/ MONTHLY PRODUCTION BY JIT

* 總用電需求 (TOTAL POWER REQUIRED):

1) 最大耗電量 (MAX POWER CONSUMPTION):127 HP, 101.3 KW

MAX. 205A, at 380V/3P/50 or 60 HZ

MAX. 356A, at 220V/3P/50 or 60 HZ

2) 平時耗電量 (NORMAL POWER CONSUMPTION):99 HP, 79.1KW

MAX. 161A, at 380V/3P/50 or 60 HZ

MAX. 276A, at 220V/3P/50 or 60 HZ

* 廠房佔地 (FACTORY SIZE)

約10米 * 16 米 = 160平方米

* 設備需求 (MACHINE REQUIRED) :

1) 兩套JIT-55 整合式背心袋製造設備 TWO SETS JIT-55 JANDI'S T-SHIRT BAG MAKING LINE

a) 最大耗電量 (MAX POWER REQUIRED) : 114 HP, 91 KW

Max. 89 A * 2 sets = 178A, at 380 V/3P/50 or 60 HZ

Max. 155A * 2 sets = 310A, at 220V/3P/50 or 60 HZ

b) 平時耗電量 (NORMAL POWER CONSUMPTION):91 HP, 72.8 KW

Max. 72 A * 2 sets = 144A, at 380 V/3P/50 or 60 HZ

Max. 124A * 2 sets = 248A, at 220V/3P/50 or 60 HZ

2) 一台空壓機 ONE SET AIR COMPRESSOR TWO SETS JIT-55 JANDI'S T-SHIRT BAG MAKING LINE

a) 最大耗電量 (MAX POWER CONSUMPTION):10 HP, 8 KW

Max. 21 A at 380V/3P/50 or 60 HZ

Max. 36 A at 220V/3P/50 or 60 HZ

b) 平時耗電量 (NORMAL POWER CONSUMPTION):5 HP, 4 KW

Max. 11 A at 380V/3P/50 or 60 HZ

Max. 18 A at 220V/3P/50 or 60 HZ

3) 一台混合機 ONE SET MATERIAL MIXER TWO SETS JIT-55 JANDI'S T-SHIRT BAG MAKING LINE

a) 耗電量 (MAX POWER CONSUMPTION):3 HP, 2.3 KW

Max. 6 A at 380V/3P/50 or 60 HZ

Max. 10 A at 220V/3P/50 or 60 HZ

* 產量 (PRODUCTION CAPACITY)

65 kg/hr * 24 hr * 26 days * 2 sets = 81 tons/Month

* 每班最少人工需求 (MINIMUM MANPOWER REQUIRED/PER SHIFT)

1 supervisor, 1 worker, 2 for packing 經理一名, 操作師傅一名, 包裝工人兩名

Details of Normal Factory 傳統生產工廠詳細資料

月產量80噸背心袋, 傳統生產工廠

T-SHIRT BAGS 80 TONS/ MONTHLY PRODUCTION

* 總用電需求 (TOTAL POWER REQUIRED):

1) 最大耗電量 (MAX POWER CONSUMPTION):188 HP, 147.3 KW

MAX. 199A, at 380V/3P/50 or 60 HZ

MAX. 346A, at 220V/3P/50 or 60 HZ

2) 平時耗電量 (NORMAL POWER CONSUMPTION):148 HP, 116.1KW

MAX. 273A, at 380V/3P/50 or 60 HZ

MAX. 427A, at 220V/3P/50 or 60 HZ

* 廠房佔地 (FACTORY SIZE):

約15米 * 20 米 = 300平方米

* 設備需求 (MACHINE REQUIRED) :

1) 兩套GF-H55 高密度吹袋機 + 兩套GF-E2-60雙色印刷機 TWO SETS GF-H55 HDPE HIGH SPEED INFLATION MACHINE + TWO SETS GF-E2-60 IN-LINE 2-COLOR FLEXO. PRINTING PRESS

最大耗電量 (MAX POWER REQUIRED) : 116 HP, 88 KW

Max. 86 A * 2 sets = 172A, at 380 V/3P/50 or 60 HZ

Max. 150A * 2 sets = 300A, at 220V/3P/50 or 60 HZ

平時耗電量 (NORMAL POWER CONSUMPTION):91 HP, 72.8 KW

Max. 70 A * 2 sets = 140A, at 380 V/3P/50 or 60 HZ

Max. 122A * 2 sets = 244A, at 220V/3P/50 or 60 HZ

2) 一台GF-JD32E/SVP 伺服雙電眼熱切封口機 ONE SET GF-JD32E/SVP SERVO DRIVE HEAT-CUTTING T-SHIRT BAG MACHINE

最大耗電量 (MAX POWER CONSUMPTION):20 HP, 15 KW

Max. 39.5 A at 380V/3P/50 or 60 HZ

Max. 68 A at 220V/3P/50 or 60 HZ

平時耗電量 (NORMAL POWER CONSUMPTION):16 HP, 12 KW

Max. 24 A at 380V/3P/50 or 60 HZ

Max. 41 A at 220V/3P/50 or 60 HZ

3) 一台粉碎機 + 一台GSR-45 廢料回收機 ONE SET CRUSHER + ONE SET GSR-45 PLASTIC RECYCLING MACHINE

最大耗電量 (MAX POWER CONSUMPTION):45 HP, 34 KW

Max. 89 A at 380V/3P/50 or 60 HZ

Max. 153 A at 220V/3P/50 or 60 HZ

平時耗電量 (NORMAL POWER CONSUMPTION):33 HP, 25 KW

Max. 66 A at 380V/3P/50 or 60 HZ

Max. 114 A at 220V/3P/50 or 60 HZ

4) 一台空壓機 ONE SET AIR COMPRESSOR

最大耗電量 (MAX POWER CONSUMPTION):10 HP, 8 KW

Max. 21 A at 380V/3P/50 or 60 HZ

Max. 36 A at 220V/3P/50 or 60 HZ

5) 一台混合機 ONE SET MATERIAL MIXER

耗電量 (MAX POWER CONSUMPTION):3 HP, 2.3 KW

Max. 6 A at 380V/3P/50 or 60 HZ

Max. 10 A at 220V/3P/50 or 60 HZ

* 產量 (PRODUCTION CAPACITY)

1) 吹袋印刷產量Film Production : GF-H55 + 2Color:

75 kg/hr * 24hr * 26 day * 2 sets = 46,800 kgs/month * 2 sets = 93.6 tons/month

93.6 tons – 12.5% die-cut = 81.9 tons/month T-shirt bags per month

2) 廢料回收Recycled Material :

93.6 tons * 12.5% die-cut = 11,700 kg per month (每月打孔廢料)

11,700 kg / 26 days / 10 hrs (working time of GSR-45) = 45 kg/hr (每小時廢料處理量)

* 每班最少人工需求 (MINIMUM MANPOWER REQUIRED/PER SHIFT)

1 supervisor for the whole plant 經理一名

1 worker for 2 extruders + printing machine 吹袋印刷師傅一名

1 worker for crusher & GSR-45 recycling machine 粉碎回收師傅一名

2 workers for packing 包裝工人兩名

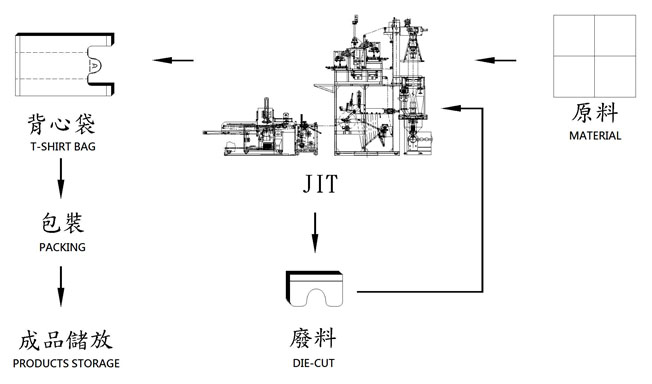

JIT Process & Factory Floor Space JIT流程圖 & 工廠佔地尺寸

背心袋以JIT即時生產之流程圖 JIT-55 JANDI'S T-SHIRT BAG MAKING PROCESS

JIT月產品80噸背心袋工廠佔地尺寸圖 JIT 80 TONS/ MOTHLY T-SHIRT BAG PRODUCTION FACTORY FLOOR SPACE LAYOUT

Normal Process & Factory Floor Space傳統流程圖 & 工廠佔地尺寸

背心袋以傳統之方式生產之流程圖 T-SHIRT BAG NORMAL PRODUCTION PROCESS

傳統月產量80噸背心袋工廠佔地尺寸圖 NORMAL 80 TONS/ MONTHLY T-SHIRT BAG PRODUCTION FACTORY FLOOR SPACE LAYOUT

T-shirt bag Production per month

背心袋生產,以月產量來比較

背心袋生產,以月產量來比較

(T-shirt bag Production per month)

背心袋傳統製程,機器組合:

Machines required for Traditional Production:

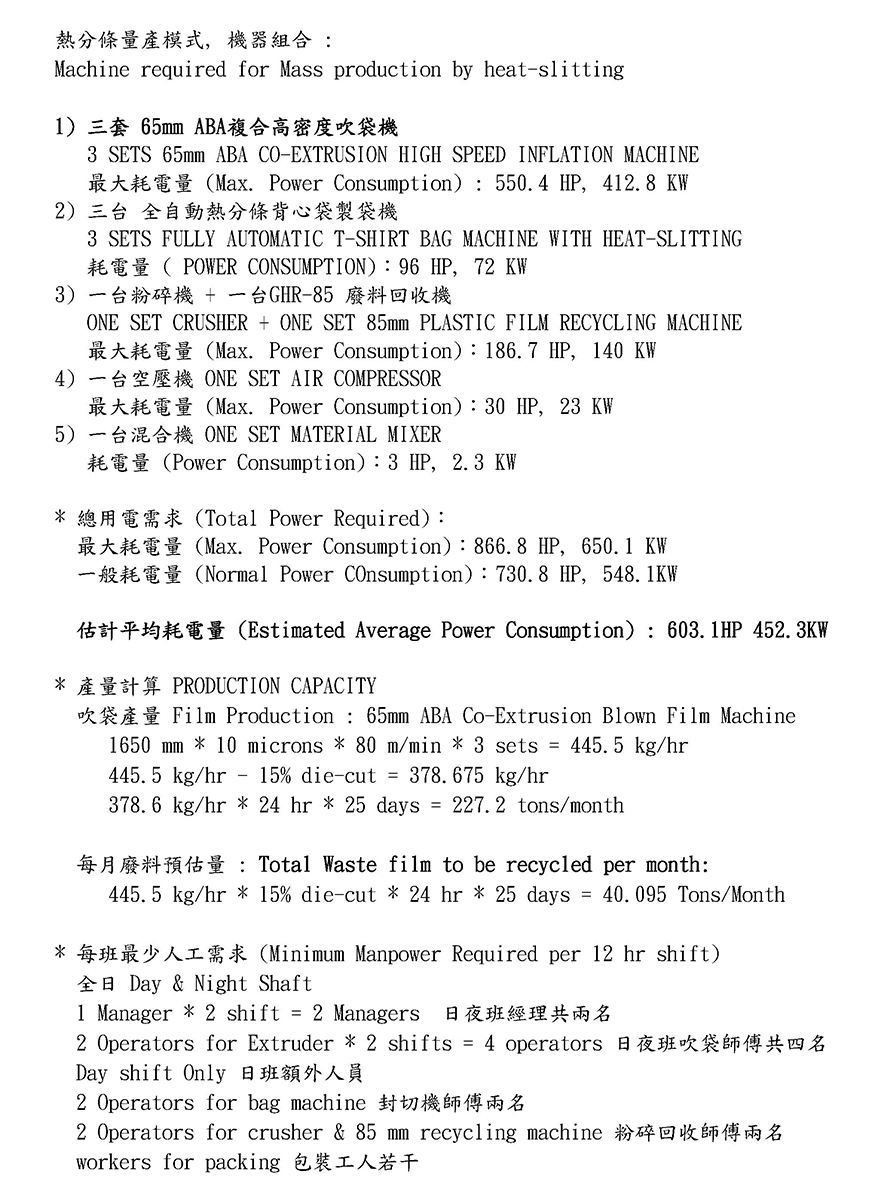

熱分條量產模式,機器組合:

Machine required for Mass production by heat-slitting:

JIT-55 整合式背心袋製造設備